Manufacturing

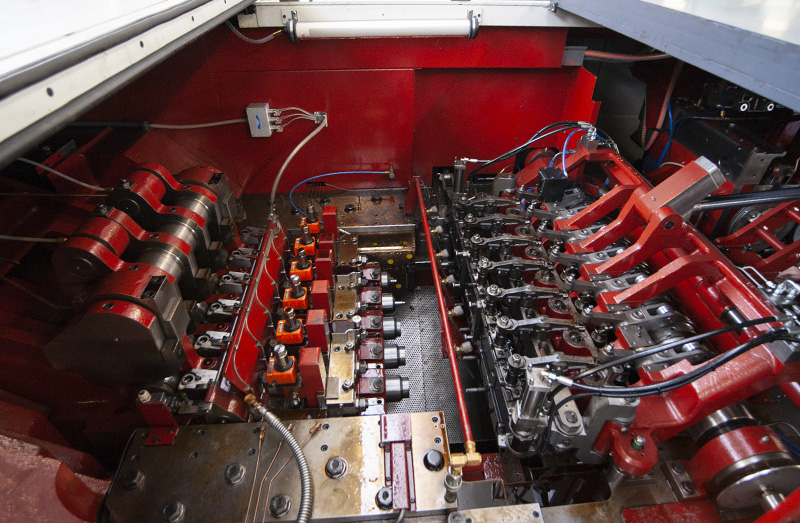

Filostamp, by using technology of wire rod deformation (metal thread) through cold forming, produces special and also complex parts, according to customer’s drawing.

Cold forming is realized through the most modern high-productivity technologies (two-strokes and progressive presses), by using various types of raw material, with a dimensional diameter range from 2,5 to 22 mm, that allow the production of bolts, screws, nuts, spacers, pins, rivets, tubular parts, hanger bolts, etc.

All processes are constantly managed and monitored according to the internal activities of the quality management system.

Thread rolling

Filostamp can supply parts with normal and special threads (grooves and toothed profiles) with diameter dimensions from 2,5 mm and 22 mm.

Machining operations

Turnings

By using special machines, Filostamp can realize machining operations by turnings on semi-finished cold formed parts, making every type of required shape (grooves, spheres, ogives, holes and “Swiss style turnings”)

Machining operations

Shearing

In addition to the operations of cold forming, thread rolling and turnings, Filostamp can realize operations through vertical forming and shearing.

100% sorting

For completing all previous production operations, Filostamp can carry out 100% sorting with optical systems on parts with special features according to customer’s request.